Meridian Logistics

Replacing spreadsheet chaos with clarity

Meridian Logistics is a regional freight company managing 200+ shipments daily across 12 warehouses. They were drowning in spreadsheets and manual processes. We built them a custom operations dashboard that transformed how they work.

Project Overview

The Challenge

Drowning in spreadsheets

As Meridian grew from 50 to 200+ daily shipments, their spreadsheet-based system couldn't keep up. Here's what they were dealing with.

17 Different Spreadsheets

Shipments, drivers, routes, inventory all in separate Google Sheets. Nobody knew which version was current. Data conflicts happened daily.

30+ Hours Manual Work Weekly

Operations team spent entire mornings copying data between systems, creating reports manually, and reconciling discrepancies.

Constant Data Errors

Manual entry meant typos, wrong addresses, and missed shipments. About 15% of shipments had some kind of data error.

Zero Real-Time Visibility

"Where's this shipment?" required calling the driver. No way to see fleet status, delays, or issues until they became emergencies.

Team Bottlenecks

Only 2 people understood the spreadsheet system. When they were out, everything ground to a halt. No documentation, no backup.

Reporting Nightmares

Weekly reports took 4+ hours to compile. Monthly analytics were basically guesswork. Leadership flew blind on key metrics.

The Solution

A unified operations command center

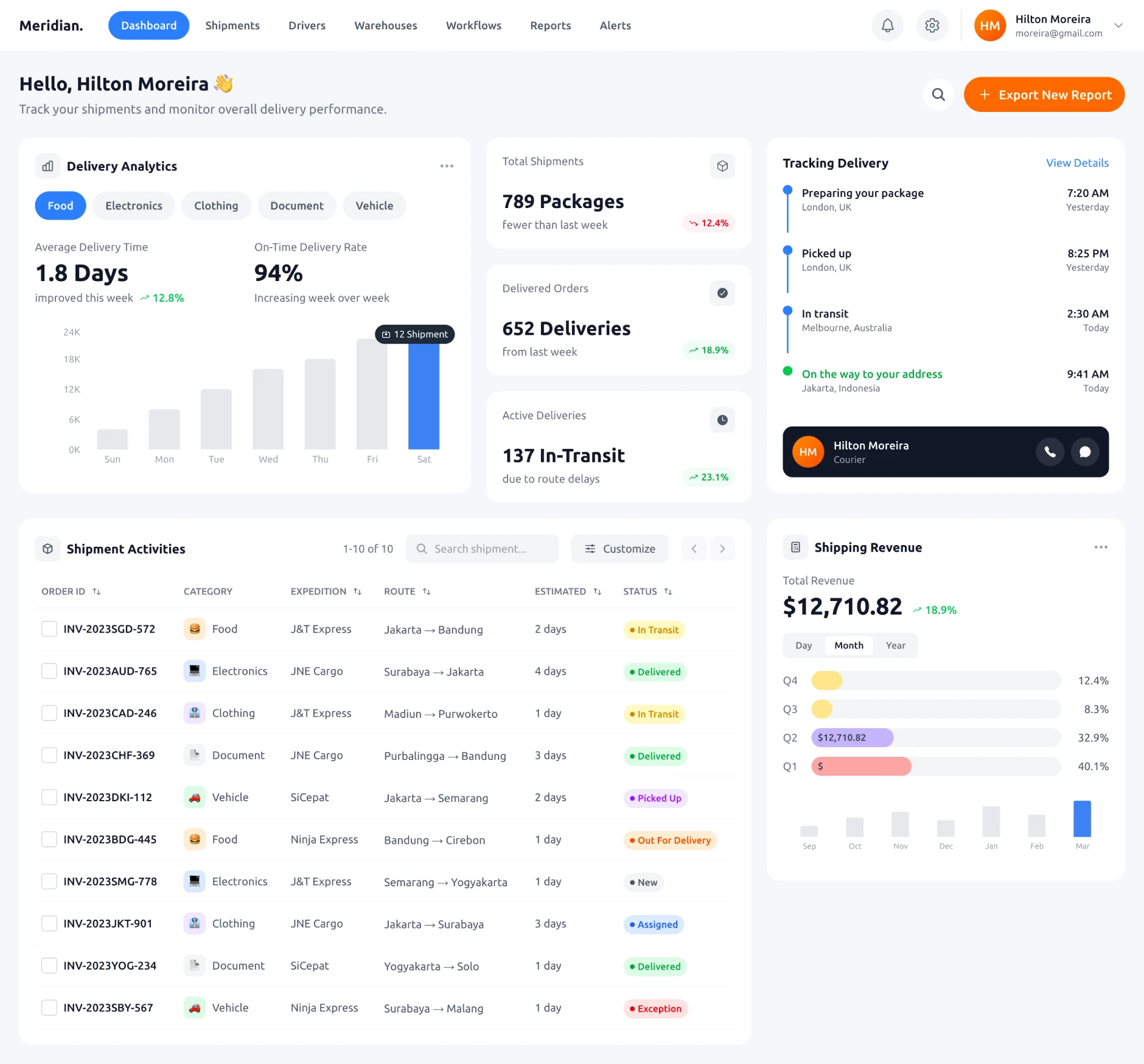

We built a custom operations dashboard that replaced all 17 spreadsheets with a single source of truth accessible to the entire team.

Real-Time Dashboard

Live view of everything happening across all 12 warehouses.

- Live shipment map – See all active deliveries, routes, and ETAs

- Warehouse status – Inventory levels and capacity across locations

- Driver availability – Who's on route, available, or off-duty

- Alert center – Delays, issues, and exceptions in one place

Shipment Management

End-to-end shipment lifecycle in one unified system.

- Quick booking – New shipments in 30 seconds with validation

- Smart routing – Auto-assign to nearest available driver

- Status tracking – Real-time updates from pickup to delivery

- Proof of delivery – Digital signatures and photo capture

Automated Workflows

Tasks that used to take hours now happen automatically.

- Auto-dispatch – Shipments auto-assigned based on rules

- Client notifications – Automatic updates at each status change

- Invoice generation – Auto-created from delivery confirmations

- Daily reports – Key metrics emailed every morning automatically

Smart Alerts

Know about problems before they become emergencies.

- Delay detection – Alerts when shipments fall behind schedule

- Capacity warnings – Low inventory and warehouse capacity alerts

- Driver hours – Compliance alerts for driving time limits

- Exception handling – Escalation paths for issues

Platform Screenshots

Technical Implementation

Frontend

Next.js, React, Tailwind CSS

Backend

Node.js, PostgreSQL, Redis

Integrations

GPS API, QuickBooks, Twilio

Hosting

AWS, CloudFront, RDS

The Process

5 weeks from chaos to clarity

Here's how we delivered a complete operations overhaul in just over a month.

Deep Discovery

Days 1-3Spent 3 days on-site shadowing the operations team. Documented every spreadsheet, every manual process, every pain point. Found 47 different data entry points.

- Process mapping workshops

- Spreadsheet audit & analysis

- User interviews (all 35 team members)

- Integration requirements gathering

Design & Prototype

Week 1Designed the dashboard UI with heavy input from dispatchers and warehouse managers. Built clickable prototypes and validated with the team before writing any code.

- Dashboard wireframes & flows

- Mobile-responsive design

- Role-specific views (dispatch, warehouse, management)

- Interactive prototype testing

Development

Week 2-4Built the core platform in 3-week sprints with demos every Friday. The ops team started using the beta after week 2 while we added features.

- Core dashboard & shipment management

- GPS integration for real-time tracking

- Automated workflows & alerts

- QuickBooks integration for invoicing

Migration & Training

Week 5Migrated historical data from all 17 spreadsheets. Ran 4 training sessions for different roles. Provided 2 weeks of intensive support post-launch.

- Historical data migration

- Role-based training sessions

- Documentation & video guides

- 2-week post-launch support

The Results

Transformation in numbers

Here's what changed in the first 3 months after launch.

Automation eliminated manual data entry. Team focuses on operations, not spreadsheets.

Data validation and automation cut shipment errors from 15% to less than 1%.

Labor savings alone paid for the project in under 4 months.

Same team now handles 23% more daily shipments without adding headcount.

Before vs After

Before (Spreadsheets)

- 17 disconnected spreadsheets

- 30+ hours weekly manual work

- 15% shipment error rate

- No real-time visibility

- 4+ hours for weekly reports

- Only 2 people knew the system

After (Custom Dashboard)

- Single source of truth

- Automated data flows

- <1% shipment error rate

- Real-time tracking & alerts

- Auto-generated daily reports

- All 35 team members trained

See It In Action

Watch the platform demo

See how the operations dashboard transforms daily workflows.

Ready to replace your spreadsheets?

Stop wasting hours on manual processes. Let's build a custom tool that transforms how your team works.